Delft’s Workshop: Re-fitting a Pickup to an old Arch-top

Delft’s Workshop: Re-fitting a Pickup to an old Arch-top

My friend Nick has a very nice old Gibson arch-top guitar. Not one of the plywood versions – it’s a fully acoustic instrument whose complex arched front was originally carved out of a large block of luthier-quality wood.

Nick loves the guitar’s sound, and he also loves the Kent Armstrong floating pickup which someone previously installed and fastened to the scratchplate. This is a specially designed humbucking pickup, thin enough to fit in the limited space under the strings of most arch-tops and not needing any screws or holes into the guitar body. It’s similar to the Bruce Bolan pickup which Gibson used to make for arch-tops – though I haven’t seen one of those for sale since many years.

The Kent Armstrong version is back-filled with epoxy and essentially noise-free. Only the scratchplate needs a little recess and a few holes to install the pickup plus volume and tone controls. In order to keep all parts of a vintage guitar undamaged, it’s possible to remove and store the old scratchplate and fit a modern replica plate to be drilled and cut for the pickup. There”s also a version which fastens to the end of the fingerboard and doesn”t need a scratchplate at all.

Armstrong”s pickups certainly do fit the majority of arch-top f-hole guitars, and they do a very good job. But they are intended for guitars whose neck is fitted to the body with a slight offset, so the end of the fingerboard floats just ‘above’ the guitar front. And as the fingerboard and upper frets are raised a little above the guitar front, so are the strings… and there is enough space underneath to fit a low-profile pickup without cutting into the guitar.

However, some older Gibson arch-tops do not have that forward offset on the neck. The end of the fingerboard is exactly level with the guitar front, and glued directly to it. This is a common construction on modern flat-top steel string guitars and semi-acoustic electrics, and it is also found on some older models of US-made arch-tops… and Nick’s guitar is one of these.

Next to the end of the fingerboard, the guitar front is quite close to the strings; but then it curves downwards and away from the strings, eventually leaving just enough height for a pickup plus a bit of string clearance. On this guitar, the closest the pickup could be fitted to the neck was about a third of the way towards the bridge. This gave a satisfactory warm tone for a jazz guitar, but unfortunately it was sitting exactly under his preferred sweet-spot for picking the strings, getting in the way and making clunking sounds when the tip of the pick hit the top of the pickup.

Originally Nick brought this guitar to me asking if I could cut some of the guitar front away so the pickup could be moved closer to the fingerboard, and out of the way of his picking. And to be fair, that is exactly what Gibson did with some of their electric arch-top models: they cut right through the front – and the internal braces – and fitted a large pick-up into the hole. I am not too worried if this is done to a semi-acoustic built with a thick plywood front, and intended to work okay with holes cut in the front. But I think this is a disgraceful thing to do to a well-made, beautiful-sounding, acoustic arch-top… and so I searched for some alternative way of getting the pickup out of the way of his picking hand, without cutting into the guitar.

Originally Nick brought this guitar to me asking if I could cut some of the guitar front away so the pickup could be moved closer to the fingerboard, and out of the way of his picking. And to be fair, that is exactly what Gibson did with some of their electric arch-top models: they cut right through the front – and the internal braces – and fitted a large pick-up into the hole. I am not too worried if this is done to a semi-acoustic built with a thick plywood front, and intended to work okay with holes cut in the front. But I think this is a disgraceful thing to do to a well-made, beautiful-sounding, acoustic arch-top… and so I searched for some alternative way of getting the pickup out of the way of his picking hand, without cutting into the guitar.

It didn’t need to move very far – about two cm towards the neck would get it away from the preferred picking area. That meant trimming about 1.5mm from the depth of the pickup case. And because the guitar top is curved both ways, it only needed all of this 1.5mm trim in the centre of the pickup, and then only on the edge facing the fingerboard. When I turned the pickup over, I noticed that the case was slightly deeper then the epoxy fill – so I could file down the metal edge level with the epoxy and that trimmed about 3/4mm off the depth) Then I looked into the dark epoxy with a very bright light an could see the two shiny coils well below the surface of the epoxy. I had no way of knowing whether there might be a vital single fine wire closer to the surface, but Nick and I had a quick discussion – about the risk of destroying the pickup vs risk of ruining guitar by cutting into it… and I had the go-ahead to file some more off the underside of the pickup. If I managed to destroy it, he would buy another one.

So I carefully filed a gentle curve out of the underside of the pickup case and the epoxy fill until I could see the shiny copper coil wires close to the surface. Happily, this gave the necessary 1.5mm trim off the pickup depth.

This is not a recommended procedure for Armstrong (or any other) pickups – it is taking a serious chance of cutting a hair-thin wire and scrapping the entire unit. But as an individual solution to an uncommon problem, we got away with it this time and I was able to refit the pickup about 18mm to the left of its original site and still have just enough clearance between strings and pickup. Nick can pick in his favourite sweet spot… and I didn’t have to cut a hole through a critical area of a nice guitar.

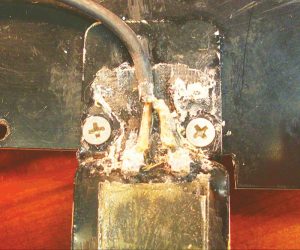

The original plan did need a bit of fine adjustment, because treble strings are usually closer to the frets than bass strings, so they are also closer to the top of a pickup. With only minimum clearance available, the pickup needed to be tilted so the scratchplate end would sit a little closer to the guitar top. I (just) managed this by bending and trimming the solder tags underneath down to a minimum, soldering the cable to the edges of the remaining stubs, and re-fitting the pickup to the scratchplate with countersunk screws underneath and nuts on top. Each of these probably gained me only a fraction of a millimetre, but together it was enough to allow the pickup to be a bit lower on the treble side. The centre of the underside of the pickup is also anchored to the guitar top with two layers of double-sided tape – which seems to hold it securely in place.

The original plan did need a bit of fine adjustment, because treble strings are usually closer to the frets than bass strings, so they are also closer to the top of a pickup. With only minimum clearance available, the pickup needed to be tilted so the scratchplate end would sit a little closer to the guitar top. I (just) managed this by bending and trimming the solder tags underneath down to a minimum, soldering the cable to the edges of the remaining stubs, and re-fitting the pickup to the scratchplate with countersunk screws underneath and nuts on top. Each of these probably gained me only a fraction of a millimetre, but together it was enough to allow the pickup to be a bit lower on the treble side. The centre of the underside of the pickup is also anchored to the guitar top with two layers of double-sided tape – which seems to hold it securely in place.

Incidentally, while it might be possible to refit a modified original neck or a new replacement to the original body, including some forward offset in the style of later arch-tops, it would be a very expensive way of installing a pickup, and more sensible to buy another guitar which is suitable for a pickup already.

I think also it would be inappropriate, because generally, similar arch-top models with raised or flush fingerboards sound different from each other, and often have different front arching and thicknessing. The end result would be an unhappy compromise and spoil a fine instrument.

I don’t really expect to see another pickup fitting job quite like this one, but if it turns out there are other folks with the same problem, I’ll buy some tiny rare-earth magnets and build a batch of super-thin pickups… My thanks to Nick for lending his guitar so I could take the photos.

Simcha Delft makes and repairs fretted instruments and old tube amps and likes to play mandola – anything from medieval music to red-dirt country.